Quality management in Novoprint S.A.

Quality management

Our quality management gives us greater efficiency, a reduction in start-up times and material costs, a better knowledge of the different raw materials (paper, inks, etc.) and of the technical requirements that affect the final result, moving in some benefits for the final customer that generate confidence and security, since we can predict the final result and ensure the consistency between jobs.

How do we deal with quality?

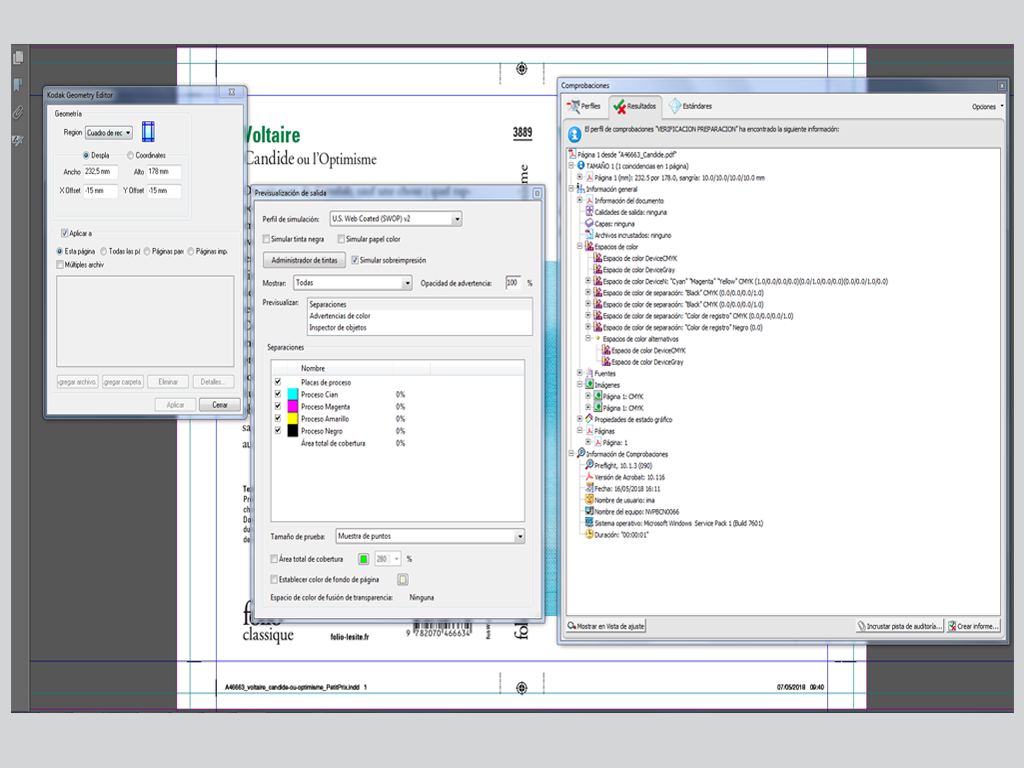

Our professional team verifies the files to ensure a good result. They control the more important specifications as file format, images, sources, colors, bleeds and margins. We help the customer to close the documents and to solve any technical doubt they may have to achieve the desired objective.

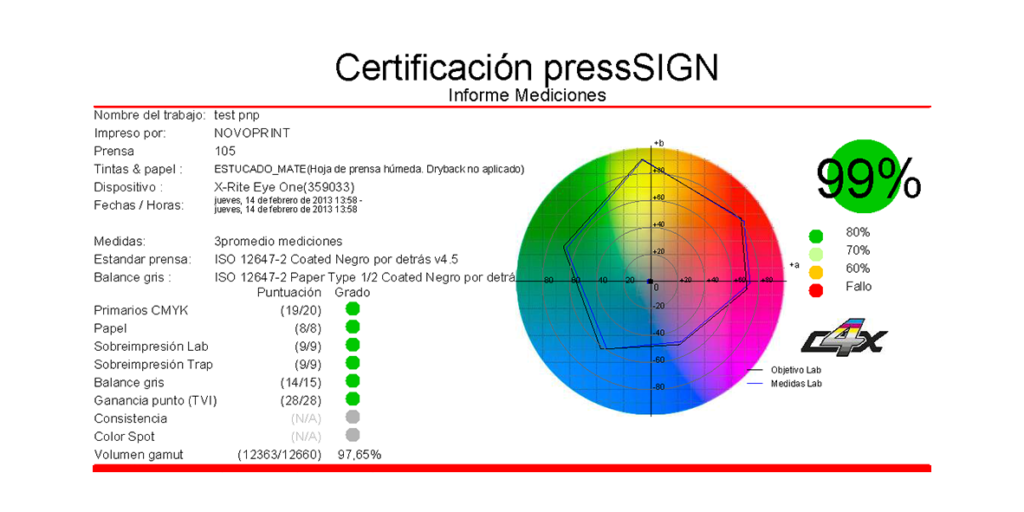

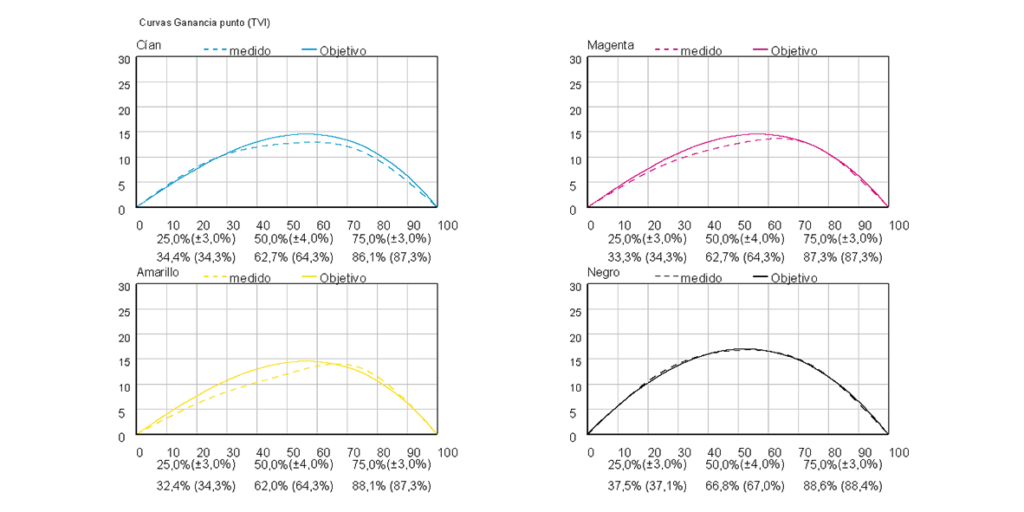

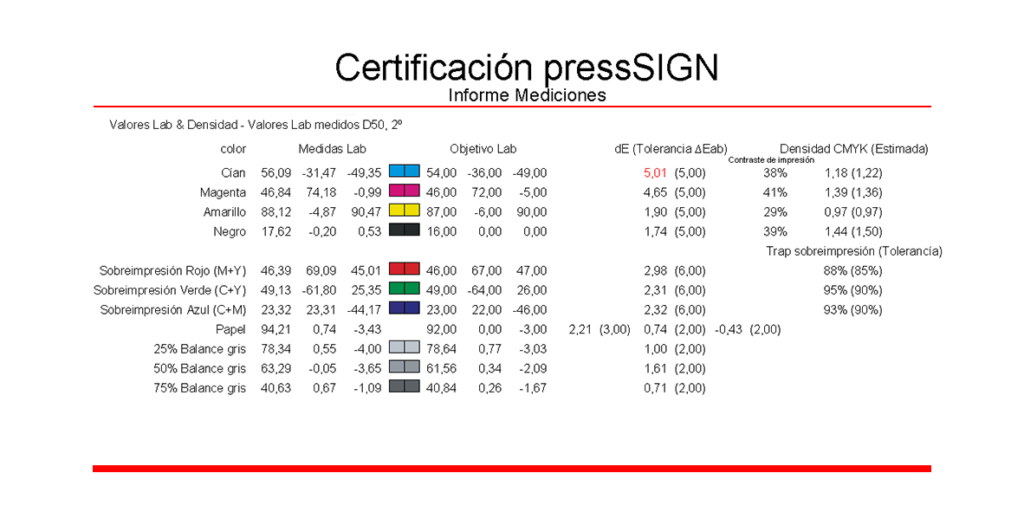

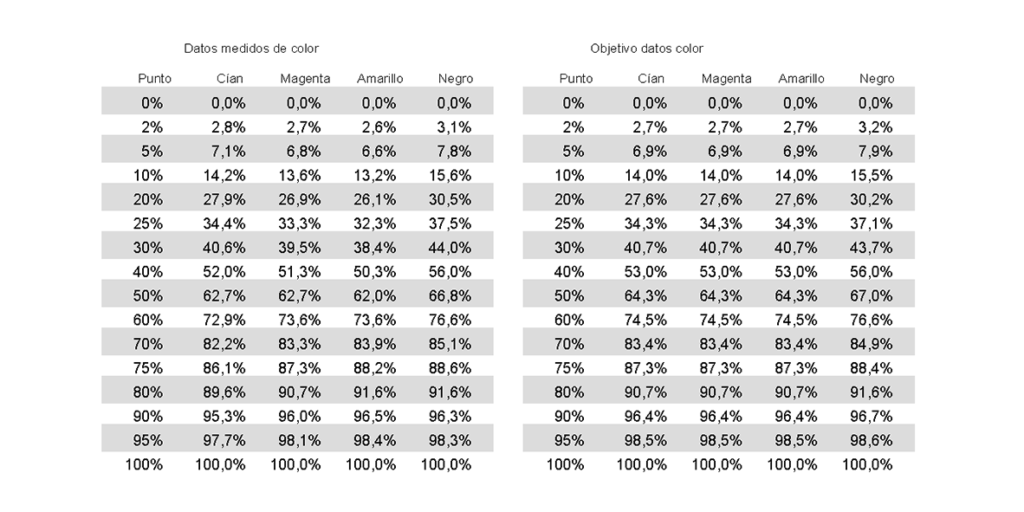

We apply an integral color management, verified by the performance of certified color tests and the application of the ISO 12647 regulation, in where there are specified the values and tolerances needed to normalize the printing process in all those primary parameters, specifying data of the screen or lines recommended and managing the color through the colorimetry of the primary inks and the data about tone increase or gain of point for the different supports and printing methods.

Our inventory management is in accordance with the needs of the company and of our customers. We apply the FIFO method in the management of raw materials in our warehouse.

We carry out controls at each stage of the production process to verify and confirm that the product is being made in accordance with the established production.

All the products are identified in our management system and it is possible to review for each of them all the traceability from its start to the final delivery, which guarantees the FSC chain of custody or other needs.